Wireless temperature & humidity monitoring systems deploy sensors and wireless technology to monitor critical climate data in real time. These systems assist plant managers and engineers in detecting shifts in air conditions quickly, reducing risk to products and equipment. Most setups integrate with cloud-based dashboards, allowing you to visualize trends and receive alerts on any device. For factories, labs, and cleanrooms, consistent control of temperature and moisture keeps everything running smoothly and complies with rigorous standards. Wireless units eliminate wiring expense and can fit anywhere, which is ideal for new or existing sites. Quick installation and minimal maintenance free time for hustling crews. My main post will demonstrate how these systems increase yields and reduce losses in hard plant labor.

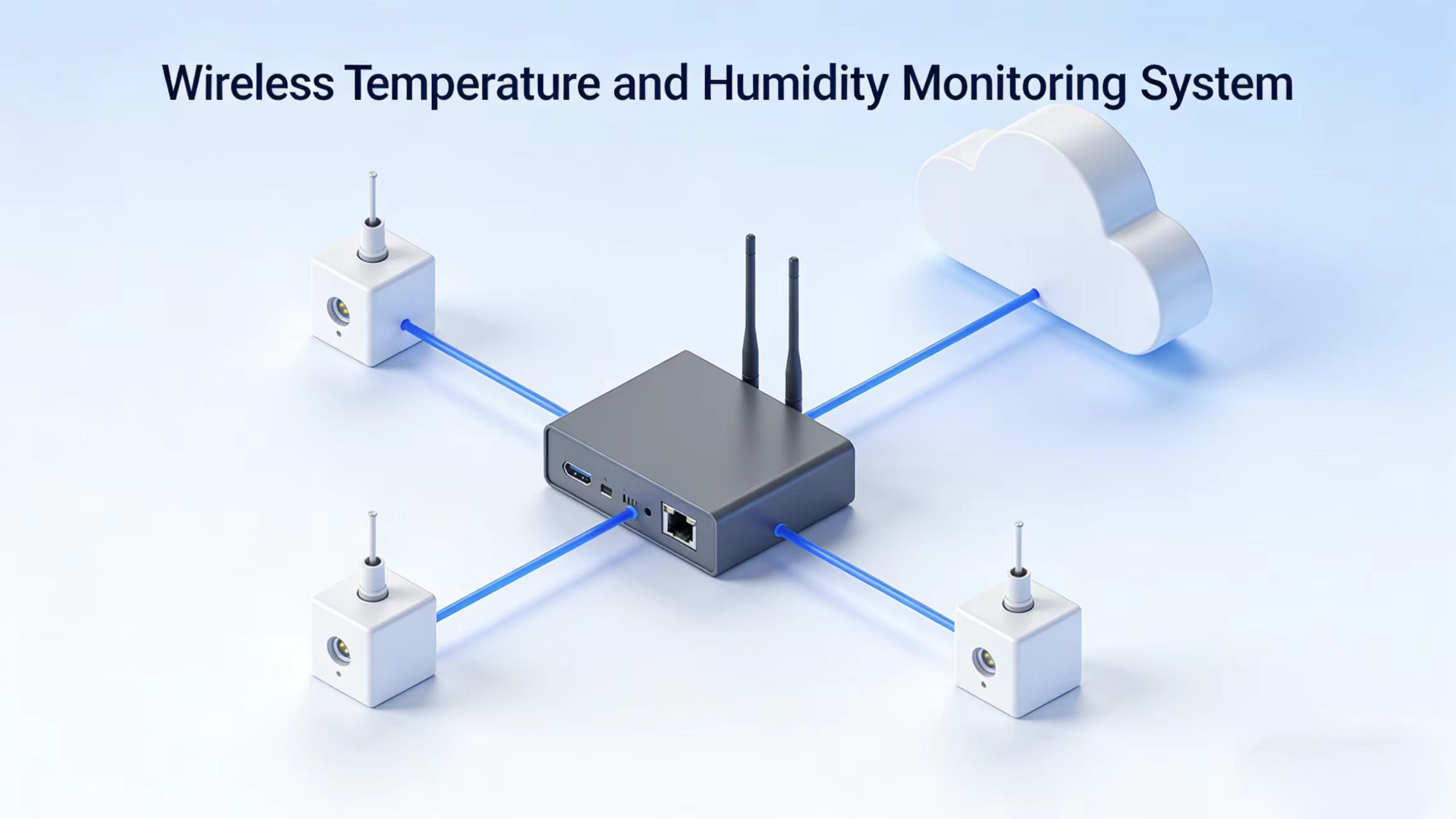

Wireless temperature and humidity monitors are composed of a combination of sensor nodes, gateway hubs, wireless protocols, cloud platforms, and user interfaces. These components serve to provide real-time, precise measurements for manufacturing environments. Gateway hubs are a central part of connecting sensors to the cloud, ensuring plant managers and engineers can monitor and react to data quickly. Their value shows in several ways:

Sensors monitor temperature and moisture in real time. Typical examples are capacitive humidity sensors and thermistors for temperature. Accuracy requires quality calibration. Factory or field calibration keeps readings snug and minimizes drift. Battery life is crucial. Smart power sensors or even energy harvesting can last years, reducing maintenance. Where you put it counts. Sensors located near heat sources or drafts may provide inaccurate measurements. For best practice, mount sensors away from machinery or vents for true environmental data.

All systems that don’t use Wi-Fi, Zigbee, or LoRaWAN. Wi-Fi is quick, but power-hungry and range limited. Zigbee and LoRaWAN both consume less power and have a longer reach. LoRaWAN can broadcast data over kilometers, through concrete and steel. These low-frequency signals are perfect for barrier-laden factories. The proper protocol depends on site requirements. For dense plants, Zigbee’s mesh works well. For sprawling locations, LoRaWAN’s range is king.

Gateways serve as the connecting point among sensors and the cloud. They gather information from tens of thousands and transmit it for evaluation. A wired gateway provides reliable, high-speed connections but restricts you to where you put it. Wireless gateways are easy to deploy and transfer. They enable remote access and alerts, allowing teams to identify problems even when off-site.

Cloud storage ensures that data is secure and accessible at any time. Teams can track trends, compare shifts and share data with partners anywhere. Privacy is important because great platforms encrypt and protect access to data. Through integrated analytics engines, cloud platforms assist in identifying trends and steering quick reactions.

At least a good interface renders the system easy to use. Dashboards, alerts, and real-time updates keep staff in the loop. Mobile apps allow users to view readings from anywhere, receive real-time alerts, and even modify settings. Custom dashboards allow every team member to track what matters most to them.

Wireless temperature and humidity monitoring systems transform how industrial sites control climate. These systems significantly simplify monitoring conditions without walking the floor or checking equipment face-to-face. Pre-wireless, employees spent hours each day gathering data by hand, frequently missing spike changes. Now a wireless system beams immediate output right to your display, wherever you are. That translates into more rapid response to issues and far less lag.

| Benefit | Wireless Monitoring | Traditional Wired Monitoring |

|---|---|---|

| Installation | Quick, minimal cabling | Complex, needs extensive wiring |

| Flexibility | Easy to move and expand | Hard to relocate or scale |

| Data Access | Remote, instant access | On-site, often delayed |

| Alerts | Real-time notifications | Manual checks required |

| Maintenance | Centralized, less intrusive | Frequent, site-by-site attention |

| Cost | Lower labor and install costs | Higher up-front and upkeep costs |

Wireless systems really come into their own in plants that operate 24 hours a day or are very spread out. With data streaming in as it happens, you detect patterns and hazards before they become expensive outages or inventory waste. For instance, a humidity spike in a pharmaceutical cleanroom triggers a wireless alert, which allows engineers to address the problem before spoilage occurs. A brief temperature drop in food processing may render it unsafe. Wireless sensors signal this when it occurs.

Cost savings arise from more than just less cabling. Wireless alternatives reduce labor and increase efficiency. You don’t require a squad stomping around with notebooks or clipboards. Instead, you receive automated logs and alerts, which means human error decreases and compliance reporting becomes easier. Wireless makes scaling up a snap. As your needs grow, simply add additional sensors. No rewiring or redesign is required.

Flexibility is the other piece. Wireless systems fit into old factories, new builds, and even pop-up setups. They flex as assembly lines shift or new spaces require monitoring. This future-proofs your site so upgrades are easy and inexpensive.

Choosing your perfect system requires a deep understanding of your site’s requirements and operational objectives. From cleanrooms to warehouses, each application has its own challenges. Key considerations should guide your choice:

Wireless monitoring systems belong where real-time data rules. Pharmaceuticals, electronics, agriculture, food processing, and cold storage are the biggest beneficiaries. In pharma, tailor-made climate control protects your products. On the farm, storing vegetables at the correct temperature prevents spoilage. Food warehouses require stable humidity to prevent molding.

Every site imposes its own restrictions. Some locations endure blast furnaces and arctic freezes, while others are bogged down in dust or ground vibration. As such, sensor placement becomes a critical procedure. Positioning sensors in proximity to doors or vents can bias readings. Big plants could require mesh networks for broad coverage. Smaller labs might desire a simpler system with fewer sensors.

One size almost never fits all. Each use case requests tracking different metrics. Some only require temperature, while others require CO₂, pressure, or even light. Identifying these needs upfront prevents waste and increases operational effectiveness.

Accuracy counts. Bad data results in product waste and risk of regulatory action. Top-notch sensors with tight tolerance and frequent calibration produce more favorable results. Seek out ISO or NIST certified systems.

Sensor drift may occur in rigorous environments. Dust, moisture, or corrosive vapors impair accuracy. If you anticipate harsh environments, opt for models with rugged enclosures. Include the expense of regular onsite recalibration.

Not all systems are created equal in terms of specs. Compare their stated margins of error. Inquire about review history and out-in-the-field performance. User reviews will expose the gotchas.

Growth is inevitable in industrial sites. A scalable system enables you to add new sensors or zones as your operation grows. Certain systems allow for modular upgrades by introducing additional nodes or gateways without a complete overhaul.

Cost scales with every additional dot. A small warehouse might get by with a simple set-up. A big plant may require an elaborate mesh network. This affects both initial and ongoing expenses.

Systems that manage expansion with easy plug and play modules conserve time and financial resources. Flexible platforms future proof your investment.

Smooth integration with your existing infrastructure is essential. Many monitoring systems now support links with HVAC controls and alarm platforms. This increases reaction time and information exchange.

Centralized data logging enhances audit trails and simplifies compliance. Open APIs allow you to integrate your monitoring data with plant management or reporting systems for greater visibility. This is particularly handy in regulated industries.

As always, compatibility checks are key. Certain legacy systems will require adapters or software adjustments in order to interface with new wireless sensors. Pick vendors that support it and have good documentation on how to integrate.

Wireless temp and humidity monitoring systems are commonplace in industrial settings today. These systems add flexibility and scalability, but they add new points of vulnerability. If we want to keep business running securely and smoothly, we must understand where systems are vulnerable and we must deploy solutions that counter both the common and uncommon threats.

Signal strength drops fast when sensors are obscured by metal walls, intense machinery, or even water pipes. Industrial sites tend to have shifting layouts, so sensors can fall into dead spots. Important to overcome system vulnerabilities, mapping wireless coverage and repeaters in large areas helps keep data flowing.

Scorching heat or ice-cold temperatures can short circuit a sensor or cause it to send inaccurate readings. Dust, moisture, and airborne chemicals accelerate wear and reduce sensor life. Selecting sensors with an appropriate IP rating and verifying specs for temperature range is an absolute necessity for harsh environments.

It’s all about strategic locations. Put sensors there and you get less noise and more signal. Don’t mount near motors, large metal objects, or equipment with strong electromagnetic fields. Mounting high may help with coverage, but sensors still need to be accessible for maintenance.

Industry-grade sensors are typically shock protected and housed in sealed enclosures. For instance, IP67 or IP68 rated sensors can resist water jets or submersion. In environments where sensors need to endure, consistent maintenance and scheduled replacements prevent malfunctions.

Industrial wireless networks confront genuine cyber vulnerabilities. OT and IT were never linked, but now they are so attacks can cross over more easily. Old wireless sensor nodes, some 7 to 12 years old, frequently operate on archaic firmware and have no protections against modern attacks.

Encryption like TLS and wireless standards including Wireless HART protect data in transit. Strong passwords, regular patching, and two-factor authentication keep out malicious users. Restricting who can get to data and implementing role-based access controls assist as well.

When a breach occurs, it can be about more than lost information. Non-compliance fines, downtime, and even safety events like a leak or explosion can happen. With open standards, firmware updates, and employee training, these risks shrink.

Taking your wireless temperature and humidity monitoring system to an industrial site is building something strong and stable and tuned for the work. These systems eliminate the guesswork in real-time climate tracking, help comply with stringent regulations, and protect equipment. It is good planning and care that make the system work in the long run.

To keep the setup in top shape requires regular maintenance. Regular checks might include sensor recalibration, battery swaps, and software updates for sensors and gateways. Cleaning sensor surfaces keeps readings true. Record every service visit to identify patterns and detect issues early. For battery-powered sites, watch voltage and switch to energy harvesting upgrades to extend sensor life.

When something breaks, isolate it quickly. Drop in signal? Scan for dead zones, interference or hardware defects. Data drifts or spikes? Recalibrate, check sensor location or moisture accumulation. If it’s not integrating with your plant’s system, test API endpoints or security settings.

Personnel who maintain and repair the system must understand how it operates. Training should address installation, live readings, upkeep, and quick repairs. Provide implementation and maintenance guides. Demonstrate how these processes are important for meeting regulatory standards, such as FDA or food safety criteria, and how to identify problems before they escalate.

Wireless temperature and humidity sensors are going fast. IoT is central to this transition. Wireless sensors are already monitoring real-time information in factories, on farms, and inside hospitals. This provides leaders real-time insights to protect people and maintain compliance. Data is then transmitted to the cloud, where algorithms detect issues in their infancy. If a storeroom gets too hot, it alerts employees immediately. That prevents spoilage, machine downtime, or product loss. In farming, IoT sensors indicate soil vitality and meteorological conditions. Farmers know when to water or fertilize, so they use less and waste less. In healthcare, wireless tracking ensures medicine and samples are kept at optimal temperatures, reducing risk and saving money.

Automation and AI are on the rise in these systems. Intelligent software has come to seek out patterns in large streams of sensor information. It reveals patterns and forecasts dangers ahead of damage. For instance, a factory system can notice if humidity increases around a delicate machine. The AI can then inform staff or even initiate repairs itself. This minimizes downtime and maintains high quality. Integration with building management systems and DCIM lets one team manage the entire site from a single dashboard. This joined-up view saves time and makes checks simpler.

IoT makes scaling easy. It’s easier to add new sensors and updates are over the air. A business can sense more spaces for less and with less clutter. Periodic maintenance, such as sensor calibration and battery swaps, keeps data accurate. Software updates introduce new features and keep the ne’er-do-wells at bay.

Sustainable. Executives need equipment that reduces power consumption, minimizes waste and complies with worldwide standards. Yakeclimate’s all-purpose systems utilize less power and assist plants to operate when they should. This reduces costs and saves the earth. More companies are eager to demonstrate their concern for the bottom line and the planet. Smart sensors and AI assist them in reaching these objectives. Going forward, more advanced data tools and machine learning will provide even greater visibility, empowering teams to respond quickly and strategize smarter.

Wireless temperature and humidity monitors now guide how plants operate. These devices detect changes quickly and reduce chances of spoilage or brief stops. Teams access real-time numbers from anywhere in the plant or office. Fast alerts allow you to fix problems before they cost you. Many plants in food, drug, and tech industries use these systems to keep products and lines running. Brands such as Yakeclimate create equipment that satisfies stringent demands and reduces waste. To keep up, explore new sensor options and find what fits your flower. Talk to a professional, measure your objectives, and see what works on your shop floor. Now, get ready to enhance your plant’s control. Contact us and begin with a test run.

For example, a wireless temperature and humidity monitoring system. Data in turn is transmitted wirelessly to a central system, enabling you to monitor conditions and receive alerts in real time from anywhere.

Wireless systems are simpler to install, convenient to move, and demand less maintenance. They cut wiring expenses and can cover large or inaccessible spaces.

Think about your needs. Consider what kind of range and accuracy you require, battery life, compatibility, and secure data for your environment.

Top systems use encrypted data transmission and secure user access. Frequent software updates and robust passwords defend against unauthorized access.

Typical hazards encompass signal disruption, battery degradation, and cyber threats. Good placement, regular maintenance, and robust cybersecurity reduce these risks.

Test sensors and batteries at least twice a year. Maintain your systems for accurate readings and long life.

Innovations include cloud integration, AI alerting, and battery-less sensors. These innovations enhance reliability, data accessibility, and energy efficiency.

Contact us to find the best place to buy your Yakeclimate solution today!

Our experts have proven solutions to keep your humidity levels in check while keeping your energy costs low.