To analyze moisture content is to test determine the amount of water present in a substance. These precise readings allow factories to protect shipments, prevent corrosion and inhibit fungal growth or rot. Most plants employ sensors or lab tests for this work. Choosing the right technique varies by product, speed, and detail desired. A number of industries, such as food, pharma, and electronics, utilize these checks to comply with regulations and maintain superior quality. Yakeclimate’s systems provide consistent, real-time information to assist with controlling airflow and maintaining moisture at safe levels. The following section highlights main methods for analyzing moisture content and what each additional step implies for work on the shop floor.

Moisture content dictates more than just the texture or appearance of a product. It affects shelf life, safety and efficacy. In food, pharma and industrial products, managing moisture is not only smart, it’s essential to efficient processing and reliable outcomes.

Moisture is a primary texture contributor in both meat analogues and numerous other foods. The incorrect water content can creep in and make meat alternatives rubbery or dry rather than juicy and tender. Protein digestibility changes with moisture—too little and they may denature, too much and they swell, altering how your body digests them. Repeatable moisture = repeatable taste, mouth feel and nutrition and that’s what customers demand. With water fluctuation comes quality fluctuation—resulting in complaints, returns, and scrap batches.

Microbes require water for growth, thus increased moisture accelerates spoilage. Even the slightest increase can ignite mold or bacteria, spoiling goods before they get to the consumer. Especially with meat substitutes, maintaining moisture stability means that flavors and texture withstand storage, keeping products fresher longer. If moisture is getting right, it can allow companies to use simpler packaging or store foods in more open conditions. High moisture requires tougher seals and cooler storage, which is more expensive.

Drying and cooking times rely on us having precise information about moisture. Over-drying kills energy and busts margin. Under-drying results in both unsafe and unusable products. Instant moisture checks reduce waste and increase productivity. For meat alternatives, precise moisture monitoring results in even cooking and reduced risk of forming defects. By maintaining moisture consistency, you reduce downtime and rework.

Food safety organizations establish rigid water boundaries for every item. Miss the mark, and it’s not just fines–it’s product recalls, lost sales and broken trust. Labels have to be consistent with what’s in there, and incorrect moisture means incorrect information on the package. Consistent, accurate analysis is the only way to remain compliant and out of legal trouble.

Reducing defects from moisture mistakes saves actual money, quick. Meat analogue makers benefit from increased margins from reduced recalls and less waste. Dry-outs or overmoisture losses in storage accumulate fast. Firms with superior moisture control provide safer, more shelf-stable products and gain more business.

Accurate moisture analysis is essential in industries where product quality, safety, or process reliability is reliant on close humidity control. Which method you should use depends on your material, your accuracy requirements, and your operational constraints. Yet innovations in measurement technology have brought greater reliability, speed and flexibility. Each method comes with its own pros and cons – and aligning the method to the application is critical for cost-effectiveness, accuracy and regulatory compliance.

Gravimetric methods determine moisture content by weighing samples pre and post drying. The traditional gravimetric method (SGM), common in food analysis and elsewhere, determines moisture from weight loss at 100C. This method continues to serve as the gold standard for moisture measurement in compliance and process environments. Its primary benefit is direct measurement, with little interaction from other sample components. Sample weighing—calibrated balances and homogeneous sample preparation—make it highly reliable. Grinding, using blenders or mincers is typical to achieve homogeneity, even for small samples down to 50 μL.

Gravimetric analysis can be slow, occasionally requiring hours of drying and cooling. It demands diligence against pitfalls—sample contamination, not entirely drying all moisture at 100–110°C (won’t get it all), and loss of volatile components. For other materials, higher temperatures or longer times are required, putting the sample at risk of degradation.

Spectroscopic methods—such as near-infrared (NIR), microwave phase shift (MPS), and microwave attenuation (MA)—allow for fast, non-destructive moisture measurement. They examine the effect of electromagnetic waves on water in the sample, enabling rapid measurements. This comes in especially handy for industries like food, pharma and textiles where sample integrity is paramount. Contemporary NIR systems can be calibrated for different matrices with standards that match the sample’s composition.

Perhaps the most important advantage is speed—moisture measurements are conducted in seconds, enabling real-time process control and reducing downtime. Non-contact techniques additionally minimize cross-contamination. Still, reading spectra requires know how, matrix effects or heterogeneity can distort results. Calibration drift, equipment expense, and routine validation remain issues.

Chemical methods, particularly Karl Fischer titration, are very precise for low-level moisture (down to 0.01% v/v). They are preferred in pharmaceuticals, specialty chemicals and certain food applications where trace moisture jeopardizes product stability. These techniques are accurate on small or heat-sensitive samples making them convenient for rigorous quality control.

Safety—titrants and reagents can be dangerous, necessitating trained personnel and strong procedures. Relative to gravimetric and spectroscopic methods, chemical analysis is slower and requires more manual effort, but is superior in accuracy at very low moisture levels. For regular process monitoring, however, it’s impractical because of time, expense and sample handling hazards.

| Method | Application Fields | Working Range | Key Strengths | Limitations |

|---|---|---|---|---|

| Gravimetric (SGM) | Food, pharma, textiles | 0.01–0.2% v/v | Accuracy, universal standard | Time, prep, temp limits |

| Spectroscopic (NIR) | Food, pharma, textiles | 0.01–0.2% v/v | Speed, non-destructive | Calibration, cost, drift |

| Chemical (KF) | Pharma, chemicals, food | 0.01–0.2% v/v | High precision, low levels | Safety, time, labor |

| Direct Physical (DPM)| food, wood, grains | 0.01–0.2% v/v | Fast, easy installation | Less accurate for certain applications

Moisture content analysis goes hand in hand with industrial process quality control, particularly for feed, food and delicate materials. Small measurement errors can derail production, affect product quality, or result in regulatory non-compliance. The variety of options—air oven-drying, vacuum-drying, freeze-drying, distillation, Karl Fischer titration, thermogravimetric analysis, chemical desiccation, gas chromatography—makes it complicated. All have their pros and cons, and findings may vary across methods. Oven temp swings are a known issue. Two ovens at the same setting may be 40 °C apart, and even a single oven will drift by 15 °C over time. These variations go right to the heart of what makes moisture readings inaccurate. The definition of “dryness” is inconsistent—weight loss may plateau, but this doesn’t always mean all water is gone or that other volatiles haven’t skewed results. Standard methods such as Karl Fischer titration are more accurate, as they directly compare to a water standard, and thus are good for calibrating empirical ones.

Sample inconsistency is a prime factor in moisture measurement errors. Any composition, granule size, or density variations within a batch can make for big swings in results. One test might not be representative of the actual average moisture content of the bulk material. Homogenization matters. Grinding or mixing samples guarantees that each test portion is representative of the entire lot, minimizing the effect of moisture pockets. This is particularly vital in feeds, grains, and composite powders.

Sample size and thickness count. Because thin or small samples dry faster and more evenly, while thick samples may trap water or volatiles, false low or high readings. At the very least, consistent sample preparation protocols. Your efforts in using splitters or mills or blenders to make things uniform will reward you with repeatable, reliable data.

Measurement methods need to account for volatiles other than water. A lot of foods and feedstuffs give off organics when heated that can evaporate with moisture during oven-drying. This can artificially increase measured moisture. It’s a more acute issue in things like herbs and spices or fat feeds. This error is especially prone to loss-on-drying and thermogravimetric methods.

To circumvent this, benchmark methods such as Karl Fischer titration or chemical desiccation focus on water alone, not all volatiles. These are favored for challenging samples. For everyday work, sticking with lower drying temperatures for shorter times can help reduce volatile losses, but this will not necessarily eliminate the problem.

Ambient temperature and humidity, for example, can affect the precision and consistency of the moisture readings. If lab air is humid, samples can reabsorb water after drying, biasing results. Inconsistent lab temperatures can affect evaporation speeds. That’s why best practice is to control lab climate—air conditioning, dehumidification, and monitoring tools keep conditions stable.

Running tests in enclosed, climate-controlled environments minimizes ambient noise. For high-precision work, you can tweak oven vapour pressure to keep a 0.01 aw water activity, guaranteeing a ‘dry’ finish no matter the external weather. These steps are important for reproducible results between tests and laboratories.

Moisture content is a primary unseen variable in industrial food production. It forms flavor, texture and aroma, determines quality, safety and shelf life, but can’t always be quantified immediately. How water binds in food, how it migrates and how it affects product stability are the unseen details that drive big processing and control decisions. Knowing these unseen variables is crucial for anyone looking to increase moisture analysis precision and satisfy rigorous industry standards.

Bound water is water trapped within food’s matrix—bound by proteins, starches, or fibers. It doesn’t drain or freeze like free water, so it serves a special function in food texture and shelf life. With meat analogues, bound water influences chew, mouthfeel, and even the shelf life. If water is bound correctly, it feels moist but won’t go mushy or dry out too quickly.

It’s not easy to measure bound water. Methods such as differential scanning calorimetry or nuclear magnetic resonance assist indicate how water plays in the food matrix. These tools can detect subtle shifts missed by standard moisture meters. Bound water moulds nutrition. More bound water typically equates to less available to microbes, making food safer and more resistant to spoilage.

Water activity, or a_w, measures how much water is available for microbes to use. It’s not the equivalent of complete wetness. A product can contain lots of water but still have low a_w if it’s mostly bound. Low a_w foods are safer and last longer—dried milk or crackers, for example.

Hygrometers or calibrated sensors test a_w directly on the line. Water activity data is crucial for food safety systems, as it directs when and how to store or pack a product. Controlling a_w, not moisture alone, reduces mold and bacterial risk, particularly in tropical environments.

Moisture sorption isotherms chart how food absorbs and releases water at specific temperatures. They indicate where water transitions from bound to free. Isotherms assist choosing the proper packaging to prevent moisture fluctuations, maintain freshness, and safeguard flavor.

When processing, reading isotherms allows engineers to establish drying times and conditions with less guess work. In meat substitutes, isotherm information maintains plant-based textures intact post-storage or shipping. Others now deploy neural networks or hyperspectral imaging to scan these patterns quickly and detect invisible moisture changes.

Precision moisture content analysis supports quality control and operational efficiency in industrial environments. Accuracy, consistency and audibility are essential to compliance and product fidelity. Every step along the way, from sample to final measurement requires scrupulous best practices.

Standardized sampling protocols reduce variability. They guarantee that every batch or production lot is contained. Cutting corners will produce a mismatch with the real-world physical state. As an example, just sampling surface layers in bulk solids can overlook moisture gradients deeper in the product.

Sample size counts. Using a too-small sample—less than 0.5 grams—can be required for rare or expensive materials but produces less accurate information. For bulk items such as grains or powders, bigger, properly mixed samples yield more dependable results. Be sure to always utilize clean, dry instruments to prevent contamination and unwanted moisture transference.

Representative samples need to be taken at several different points and depths. This minimizes random error and more accurately represents the true average. Cross-contamination, even from fingerprints or stray air, can bias findings. Wear gloves, seal samples in airtight containers, and don’t leave them out in room air staring at the clock.

Inappropriate sampling can deceive full process decisions. Erratic or polluted samples can confuse, causing false positives or negatives on moisture content — imperiling product quality and compliance.

Regular calibration is key. It keeps moisture meters and analyzers providing dependable results. Calibrate back to traceable standards or reference materials, fine tuning to the sample’s actual characteristics – i.e., specific wood species for pin meters.

Periodic calibration schedule keeps measure drift in control Monthly or quarterly checks (depending on use) are typical. Protective cases and careful handling keep damage from causing errors. Ignoring calibration can lead to systematic bias, hiding actual process shifts.

Best practices involve testing with both pin and pinless meters for cross validation, and verifying readings with reference materials. Calibration history should be maintained for traceability and regulatory purposes.

Each moisture analysis method needs to be qualified for the sample type in question. Validation verifies the method’s accuracy, precision and robustness. Select validation methods according to the measurement principle—loss-on drying may miss volatile losses; Karl Fischer analysis is more specific for water.

Statistical analysis, like repeatability and reproducibility studies, quantifies reliability. Parallel results from different methods can expose systematic limitations or errors. Steer clear of such traps as applying unvalidated protocols to new materials or neglecting periodic revalidation.

New tech is transforming the speed and accuracy with which we can analyze moisture in food and other materials. Today’s demands for rapidity, precision and auditable outcomes lead manufacturers to search for more effective methods. Next wave analyzers will be more portable, faster, easier to use. Most will interface with other devices, permitting real time monitoring and control. The desire for solutions that operate on any sample, regardless of material, continues to increase.

Real-time moisture sensors provide plant managers immediate visibility during production. These sensors reduce waiting times and detect changes immediately. Long-term, that translates into less scrap and more run time. Online systems detect moisture changes at every process step, enabling operators to act quickly to maintain spec.

Hardship lies ahead. Sensors have to operate in harsh, high-temperature or wet environments and continue to provide reliable data. Certain foods are sticky or oily and that tends to distort readings. With more material-independent sensors and new designs, food, pharma and more companies can see gains. For bread makers, grain mills or powder lines, real-time monitoring equates to less recalls and leaner quality.

Spectroscopy is becoming more acute. New machines detect moisture that’s quicker and more precise. NIR and mid-IR devices can already detect subtle moisture variations, even in complicated blends.

This tech also operates on all sorts of samples—powders, liquids, or solids—without much preparation. In labs, that translates to more scalability, less hands-on time, and better repeatability. As these approaches become more accessible, they could supplant traditional oven drying experiments or chemical analysis. NIST-traceable direct measurements are on the increase, delivering on the promise of results both labs and regulators trust.

Predictive models take data and estimate how moisture content will vary as food is processed or stored. It’s the future of moisture determination and these tools allow teams to strategize and circumvent issues before they begin.

With machine learning, models improve as they’re exposed to more data. That helps optimize dryer settings, select appropriate packaging, or configure alerts for hazardous areas. Lead to more consistent product and reduce waste. Better models The goal is simple: keep the line running, keep quality high, and save money.

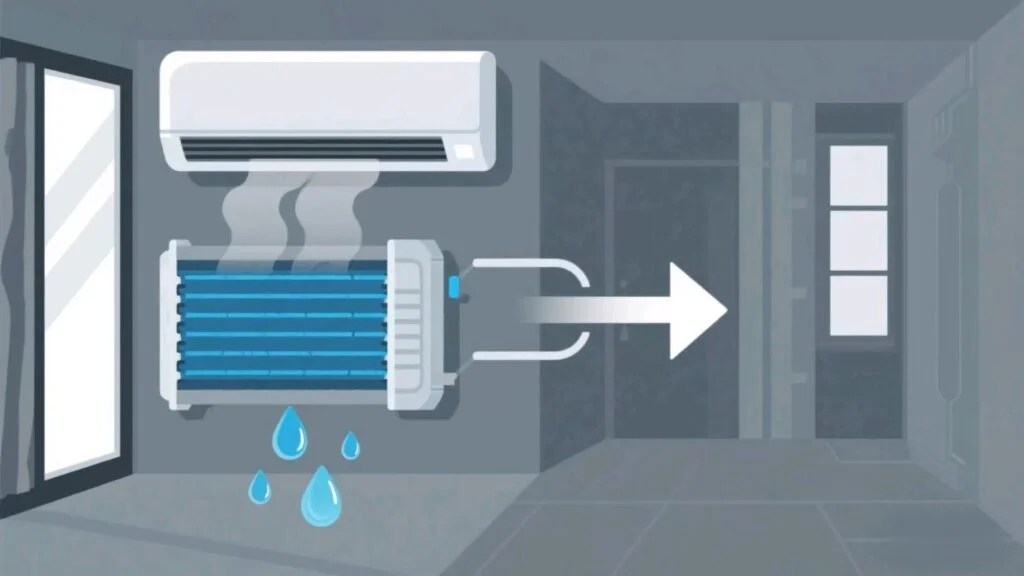

To really have control of plant air, you need to know the water in it. Great moisture checks provide hard data. Old tools don’t catch subtle changes. Now, fast, smart sensors help catch small spikes. A couple of grams of water in the air will ruin a car finish in a paint booth. In a pill plant, moist air can ruin an entire batch. Good gear, rigged just right, translates to smooth lines and powerful checks. Tech keeps ticking, with smarter sensors that work even faster and require less maintenance. To slash waste and stay affordable, stay on top of the latest methods to analyze moisture content. For assistance with the appropriate equipment or configuration, contact a climate technology expert.

Moisture content analysis quantifies the water present in materials. It is crucial for quality control in industries such as food, pharmaceuticals and construction materials.

It guarantees the quality of products, helps avoid spoilage and complies with safety regulations. It saves companies from expensive losses and preserves customer confidence.

Popular techniques are oven drying, Karl Fischer titration, and infrared analysis. Different techniques are appropriate for different substrates and precision requirements.

Sample contamination, uneven heating, and equipment calibration can skew results. With the right techniques, you can minimize mistakes and maximize consistency.

As always, calibrate equipment, follow SOPs, and use clean, representative samples. Daily inspections and employee education improve consistency.

They the “unseen variable” often means hidden moisture or variables like humidity that can throw off test results.

These new technologies employ sensors, automation, and real-time monitoring. These innovations render moisture analysis quicker, more precise and simpler to operate worldwide.

Contact us to find the best place to buy your Yakeclimate solution today!

Our experts have proven solutions to keep your humidity levels in check while keeping your energy costs low.